OUR FACILITIES

In 2016, we opened the first phase of our most recent facility expansion with Building #1, a 20,000-square-foot hub that serves as the heart of our internal design and manufacturing operations, featuring departments like Assembly, Engineering (R&D), and Quality, along with a cafeteria, fitness center, and conference spaces. In 2018, we expanded our capabilities with the opening of Building #2, a 12,000-square-foot extension site, which houses our Information Technology (IT), Surface Mount Technology (SMT), and Machine Shop departments.

OUR DEPARTMENTS

The ARS Difference is defined by our 100% internal onsite production capabilities, where a dynamic cohesion of specialized departments drive our success.

Our Assembly and Surface Mount teams expertly integrate components, handling complex electronic placements with precision and finesse. In the Machine Shop, advanced equipment is used to fabricate and customize parts, while the Chassis team ensures robust, reliable structures for our proprietary technology. Throughout our design and manufacturing process, the Documentation team meticulously records technical details to support quality, compliance, and generative technological advances.

Innovation is the heart of our Research & Design (Engineering) department, where new ideas are developed into cutting-edge solutions. Within the stock room, our Purchasing and Material Management team maintains high standards for raw materials, providing accurate lead-times and supporting efficient production. Quality Assurance enforces rigorous standards, and the Test team performs thorough evaluations to guarantee every product's performance and reliability.

THE "ARS DIFFERENCE"

MAKES THE DIFFERENCE

THE PROOF IS IN THE PRODUCTS!

RESEARCH & DESIGN

INVENTING FOR TOMORROW: OUR FORESIGHT FRAMEWORK

THE SPARK OF INNOVATION STARTS WITH DESIGN

At ARS Products, our Research and Design team champions design thinking and the product design cycle as fundamental practices to drive innovation and excellence. By focusing on a user-centric approach, we develop each product with a deep understanding of user needs and challenges, ensuring that our solutions are both effective and impactful.

Our iterative design process—comprising of empathizing, defining, ideating, prototyping, testing, and implementing—allows us to continually refine and enhance our solutions, keeping pace with evolving industry needs. Our commitment to the design cycle is a crucial element that underscores and informs our production practices, further enabling a seamless transition from conceptualization to execution with both precision and agility.

Our integrated approach ensures that each product not only meets but exceeds expectations, reflecting our dedication to quality and user satisfaction.

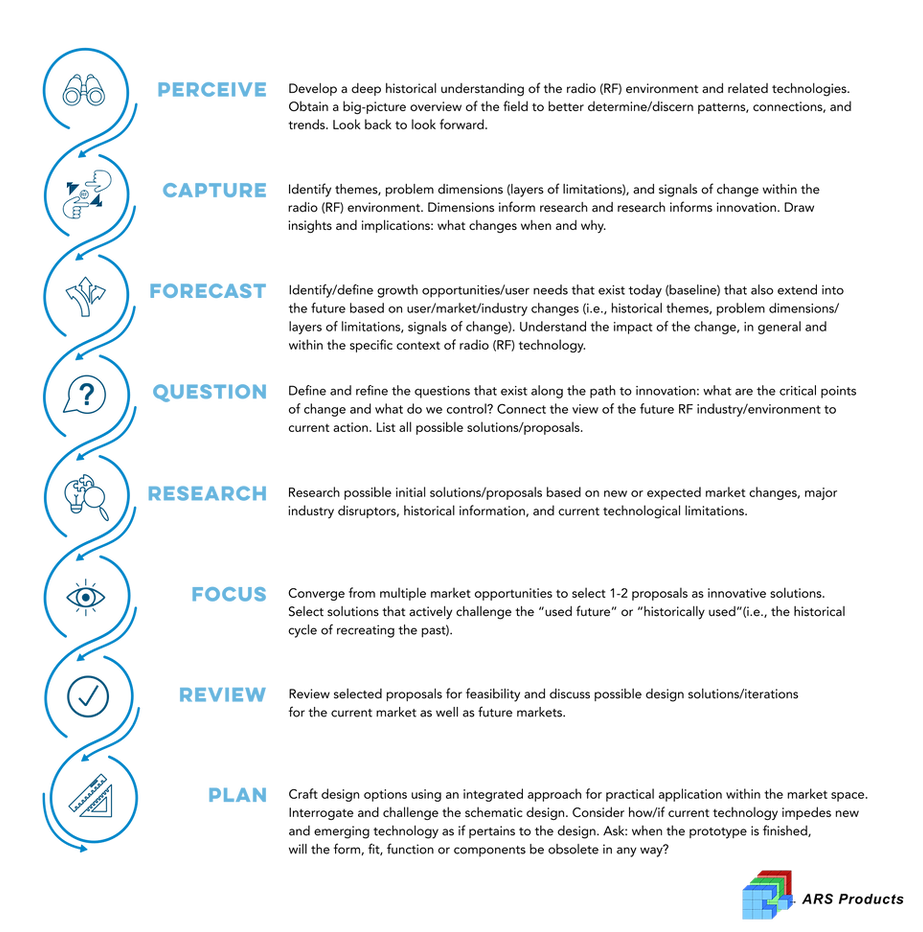

At ARS Products, we seamlessly integrate foresight and design thinking to drive our agile product development process. By capitalizing on our foresight framework, we are able to anticipate future trends and technological advancements, allowing us to stay ahead of the curve and address emerging needs with precision.

Our forward-thinking approach is paired with established design thinking methodology, which focuses on understanding user needs and crafting innovative solutions that are both functional and intuitive. Our three-phase practice ensures that our product development is responsive to current market demands and adaptable to future changes. Our agile strategy enables us to iterate quickly, incorporate feedback dynamically, and deliver cutting-edge RF solutions that meet the evolving expectations of our clients and the broader communications industry.

By combining foresight with design thinking, ARS Products maintains a competitive edge and continually pushes the boundaries of innovation in the RF sector.

AUTOMATED CAPABILITIES

Our automated testing and assembly capabilities are at the forefront of our production excellence, leveraging cutting-edge technology to ensure precision, consistency, and efficiency. Since 2016, we have integrated advanced automation systems into both our testing and assembly processes, minimizing human error and maximizing throughput.

Our Quality Assurance and Test departments capitalize on our automated testing equipment to rigorously evaluate every component and product, ensuring they meet the highest quality standards before reaching the end-user. In tandem, our automated surface mount robot helps facilitate rapid, consistent, and error-free production, enabling us to scale operations while maintaining exceptional quality.

MICROCRAFT - EMMA

FLYING PROBE TESTER

At ARS Products, all unpopulated boards for ARS-manufactured technology undergo electrical testing with EMMA before being processed into our system. Upon receiving unpopulated boards from our trusted vendors, our Quality Assurance team first conducts thermal exercises before performing an electrical inspection with Microcraft's Flying Probe Tester (EMMA).

Utilizing EMMA on our production line has eliminated concerns regarding broken plating, through holes, vias, silk-screen errors, design errors, and defects. By cycling every board through EMMA as part of our quality policy, we ensure that every connection within the stack, both internally and externally, is fully operational and functioning within our standard performance range.

On average, our Quality Assurance team can process approximately 12 to 20 boards per hour, depending on complexity and size. The integration of Emma into our manufacturing process has not only reduced production time but also enhanced performance consistency across all our products.

EUROPLACER -

PICK & PLACE ROBOT

Once we receive a purchase order, the previously inspected unpopulated boards are sent to our Surface Mount team in Building #2 for stencil printing (ASYS Group - Ekra), surface mount component placement (Europlacer Pick & Place Robot IICO), and then heated and cooled to solidify the solder paste/joints (BTU International – Pyramax 100A). Following this, the boards are visually inspected using the Mirtec 6 - 3D AOI Series.

Throughout the SMT (Surface Mount Technology) production line, each board undergoes additional visual inspections—both manual and automated—before being washed and sent for a secondary quality inspection. By incorporating frequent and thorough visual inspection points throughout the SMT process, we ensure 100% capture of placement errors, design changes, and defects before any boards are placed into a chassis unit for final testing.

The Europlacer Pick & Place Robot IICO has significantly streamlined our production cycle. What once took 1-2 business days to populate by hand now only takes 8-12 minutes per side, depending on the board's complexity and the number of components. On average, we accurately populate 2-4 boards per hour (front and back), with approximately 515-570 component placements per side.

MIRTEC 6 - 3D AOI SERIES

(MV-6 OMNI)

The Mirtec 6 AOI – Automated Optical Inspection system utilizes advanced 3D volumetric analysis through sophisticated light profiles to deliver immediate and precise feedback on our SMT-populated boards. Strategically integrated into our SMT production line, the Mirtec 6 is positioned just after the cooling section of our Pyramax oven, ensuring that component placement is fully solidified and secure. Once the boards have cooled, they are gently conveyed into the Mirtec for meticulous inspection. Using a pre-programmed profile tailored to each specific assembly build, the Mirtec 6 meticulously examines part presence, part marking, and polarity, while also performing an exhaustive solder inspection. This cutting-edge technology significantly elevates our accuracy in reporting, guaranteeing that no board exits our Surface Mount production area with any detectable failure.

EXATRON - SINGLE SITE

& THERMAL IC TEST

The primary purpose of our Exatron IC Single Site & Thermal IC Test is to ensure that all of our COTS (commercial off-the-shelf) relays are reliable and ready for use. Just as all our PCB boards are tested upon arrival at our facilities, every purchased relay is also tested for performance and continuity before implementation.

Relays are crucial components in electronic circuits, especially in radio frequency applications. The Exatron verifies continuity by exercising each relay with 100 switching cycles, identifying any failures and their causes well before the relays enter our stock room. In 2 to 3 hours, our Exatron can test approximately 400 relays, documenting any failures and associated causes for further investigation. Not only do we test our relays prior to population (automated batch test via Exatron), we also manually test them after population in our Test department to further guarantee the long-term performance and reliability of our technologies.

THE ARS DIFFERENCE EXPERIENCE

DEPARTMENTS & FACILITIES VIRTUAL TOUR

.png)